Hot products

Product details description

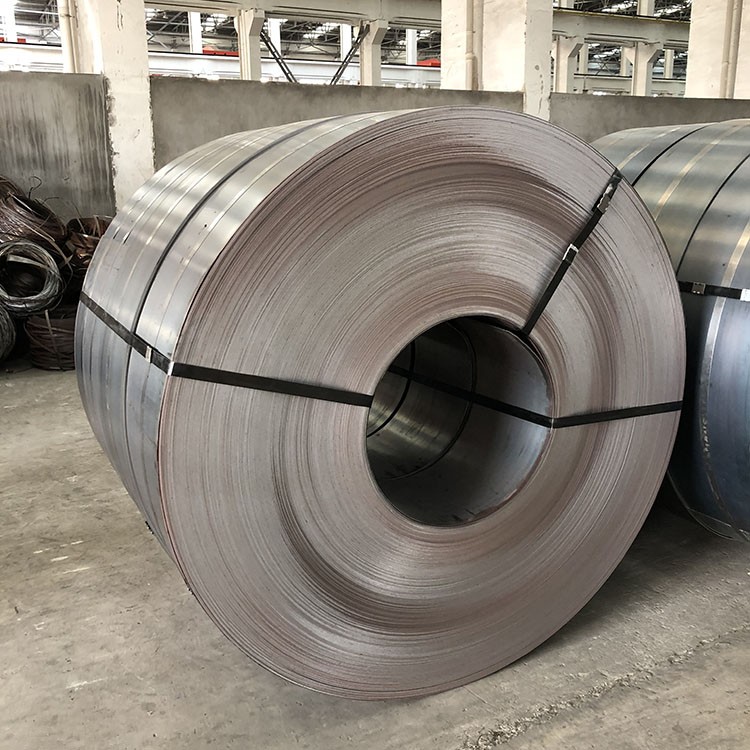

Composition:Carbon Steel Coil is a continuous, wound flat sheet product made from carbon steel—an alloy primarily composed of iron and carbon. The composition may include trace amounts of other elements depending on the specific grade.

Production Process:The manufacturing process involves melting iron ore with carbon in a blast furnace, refining the molten metal, and then shaping and cooling it into coils through processes like hot rolling or cold rolling. Heat treatment may be applied to achieve desired properties.

Grade A36

Composition: Iron, carbon; trace elements.

Applicable Standards: GB/T 3524-2015 (China), ASTM A36/A36M (International).

Applications: General structural purposes, construction.

Grade Q235

Composition: Iron, carbon, manganese, silicon.

Applicable Standards: GB/T 3524-2015 (China), ASTM A36/A36M (International).

Applications: Structural components, automotive frames.

Grade SAE 1008

Composition: Iron, carbon, manganese, phosphorus, sulfur.

Applicable Standards: GB/T 3524-2015 (China), ASTM A621/A621M (International).

Applications: Automotive parts, pipes, wire rods.

| Property | Description |

|---|---|

| Material Composition | Primarily iron and carbon, with varying alloying elements in different grades |

| Manufacturing Process | Involves melting iron ore with carbon, refining, shaping, and cooling into coils through hot or cold rolling |

| Types | Grades such as A36, Q235, SAE 1008, each tailored for specific applications |

| Applications | General structural purposes, construction, automotive components, various structural applications |

| Characteristics | Mechanical properties vary based on grade, offering combinations of strength, hardness, and formability |

| Size and Dimensions | Available in various widths, thicknesses, and lengths to meet specific application requirements |

| Surface Finish | Options may include pickled, oiled, or coated for improved corrosion resistance |

| Applicable Standards | GB/T 3524-2015 (China), ASTM standards for each corresponding grade |

| Manufacturers | Numerous steel manufacturing companies globally |

| Long-term Performance | Known for durability and strength in a variety of applications over an extended period |

| Considerations | Selection based on grade, required properties, application conditions, and industry standards |